03-December-2021

Glow plugs: the byword is quality

The focus of the market and public opinion is increasingly driven by a future based on hybrid and electric mobility, and vehicles from this category are becoming more and more common on our roads.

However, diesel engines remain a cornerstone of contemporary mobility and, thanks to the latest developments and the levels reached with Euro6 technology, they produce nitrogen oxide emissions in line with petrol engines.

Therefore, the diesel engine is still an efficient solution, and it is not hard to imagine that it will continue to exist, even with the accelerating transition towards hybrid - including diesel - and electric motors. It goes without saying that together with the diesel engine itself, there is still demand for all the relative specific components. First and foremost, glow plugs.

This is why at Magneti Marelli Parts & Services we continue to invest in their development, in order to obtain ever higher quality components. Additionally, very efficient glow plugs optimise fuel consumption in increasingly sophisticated diesel engines, thus contributing to achieving the levels provided for by the Euro6 standard (now updated in Euro6 D).

A quality range

Our range of glow plugs is extensive and complete, covering 95% of the vehicles currently on European roads, and is constantly updated in terms of innovation and application. Above all, it is a range made with high-quality materials capable of resisting chemical, electrical and intense mechanical stresses, guaranteeing ultra-rapid cold starts even in extremely harsh environmental conditions, as well as lower fuel consumption. The exclusive use of high-quality materials is a fundamental aspect for guaranteeing low emissions from diesel engines, to respect the standards of major vehicle manufacturers and to remain in line with our company values. This is why our glow plugs comply with the highest sector standards in terms of quality and production, including ISO 6550, ISO 7578 and the recent ISO 17447-1 2015 certifications.

The range of Magneti Marelli Parts & Services glow plugs is divided into 3 types, all the latest sector technology capable of perfectly satisfying all application requirements:

- Self-regulating: Metal glow plugs with dual filament, equipped with modern pre- and post-heating technology. They are made to remain on for up to 3 minutes after engine start, if called on to do so by the control unit, in order to reduce noise and harmful emissions to a minimum.

- Instant heating: Metal glow plugs equipped with Instant Start System - ISS technology, offering optimal performance and variable power supply that, due to particular build characteristics and appropriately managed by the pre-heating control unit, reach working temperature in approximately 2 seconds. Engine starting is consequentially practically instant, in line with petrol engines, even in extremely harsh environmental conditions (temperatures as low as -25°C). They are designed to work in combination with an electronic control unit that governs power consumption. The power absorbed and the consequential variation in temperature is managed in accordance with the demands from the engine in every specific moment. These glow plugs can be activated by the control unit even after engine start and at any time that the conditions in the combustion chamber require so. As a result, the combustion process is constant and stable, and both harmful emissions and consumption are reduced to a minimum.

- Ceramic-type ISS glow plugs: Instant heating glow plugs that are equivalent to OE ceramic glow plugs in terms of function, size and performance. The latter aspect has become fundamental in satisfying increasingly stringent regulations in terms of pollution for the new generations of diesel engines. Due to their capacity to withstand higher working temperatures, ceramic-type glow plugs contribute to a reduction in emissions and fuel consumption, guaranteeing compliance with the strictest specifications. They are equipped with ISS technology and differ from instant heating models due to the presence of a dual filament welded with the special alloy Inconel 601. They are made to achieve both extremely brief heating times, up to 950°C in less than 2 seconds, and high temperatures in the post-heating phase, up to a limit of 1150°C.

Our glow plugs guarantee high performance, extensive durability and reduced consumption. High product quality is ensured by the specific experience of Magneti Marelli Parts & Services which, thanks to constant collaboration with major vehicle manufacturers, is capable of offering products that respond perfectly to the demands of every engine.

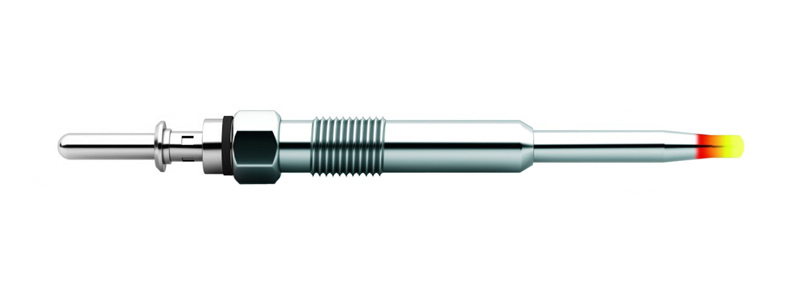

How they are made

The type of material used to make the glow plugs is the first important factor in recognising a quality product.

Latest-generation Magneti Marelli Parts & Services glow plugs, developed and produced in Italy, consist of:

- Dual filament and electrode: the glow plugs have a dual filament. The first, made with a cobalt-iron alloy (CoFe8), is known as the regulating filament as it modulates the temperature of the glow plug during prolonged post-heating phases. The second, in an iron-chrome-aluminium alloy (Kanthal), that provides considerable resistance to high temperatures, is known as the heating filament as it increases the temperature in the combustion chamber, facilitating ignition. The two filaments are powered by electrodes made of metal plated in copper for increased electrical conductivity. These elements allow the glow plugs to regulate the temperature over time and to be able to remain on for extended periods, rendering the diesel engine less noisy and odourless and allowing it to consume less fuel and have lower emissions.

- Insulation seal: a ring made from Viton, a material that offers excellent heat resistance, which seals the insulating magnesium oxide (Mg0) powder, together with the dual filament and the electrode, protecting it from infiltration.

- Metal sheath: a sheath made from Inconel 601, a special nickel-chrome-iron alloy with exceptional resistance to oxidisation, corrosion and high temperatures. The sheath encloses the dual filament and the electrode that are bathed in the insulating powder (Mg0), guaranteeing increased solidity and mechanical resistance.

- Glow plug body: the body of the glow plug contains and protects the heating elements and is threaded to allow the glow plug to be screwed into the engine head. It is comprised of nickel-plated metal, which provides increased resistance to corrosion and oxidisation.

- Insulating terminal and ring: the terminal, made from nickel-plated metal, connects the glow plug to the control unit, from which it receives electrical power. The insulating ring, made from polyamide, separates the part of the glow plug that is inserted into the engine head from the external section, and ensures both mechanical resistance and electrical insulation.

In order to guarantee low emissions from diesel engines, quality counts from start to finish. Put your trust in the range of Glow Plugs from Magneti Marelli Parts & Services!

-

NEWS2024-04-02Magneti Marelli Parts & Services: a full range of A/C solutions for all workshop requirements

-

NEWS2024-03-07Magneti Marelli Parts & Services: spark plugs and glow plugs for engines in perfect efficiency

-

NEWS2024-02-22Magneti Marelli Checkstar supports Nicolò Bulega in the 2024 Superbike Championship

-

NEWS2024-02-19Magneti Marelli Parts & Services: a braking range that is perfect for every need

-

NEWS2023-12-11Magneti Marelli Parts & Services at IAAF

-

NEWS2023-12-05Magneti Marelli Parts & Services shock absorbers: a full range to satisfy market demands

-

NEWS2023-11-28Tamara Molinaro: exploring the essence of Extreme E

-

NEWS2023-07-11Magneti Marelli Parts & Services renews its own-brand range of timing-chain kits